Why most company Use a 10 Zone Force air convection reflow oven?

Most SMT assembly line company uses the ten zone force air convection reflow soldering system because it delivers more accurate thermal control and has power efficient technology. It also has a process capability that spans from simple, one layer PCBs to complex, 20 layer, thick PCBs.

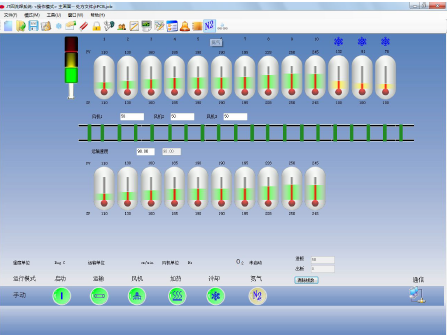

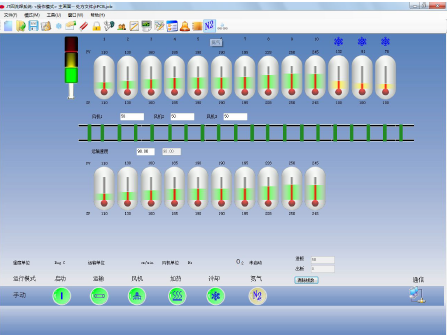

Ten zone force air convection reflow soldering system produces ?T’s less than ±0.8°C with hot air evenness and less than ±1.0°C with PCB thermal evenness. Consistent thermal performance of the thermal control technology promotes excellent zone separation, minimizes cross board ?T’s, and allows for better control of time above liquidus.

Ten heat zones mean there are ten top and ten bottom heat elements in the chamber and they can be controlled individually. The temperature profile can be adjusted very accurately in order to handle different applications.

New cooling configurations allow the filtered or reclaimed air back to the oven chamber. It reduces the thermal loss as well as gets better flux reclamation. The Cooling fans’ speed can be controlled so they meet cooling slope requirement on thermally-challenging board assemblies.

QISMT Electronic Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, Insert Plug-in machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Production line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Skype: qismteric, Email:sales@qismt.com